|

By controlling spindle rotation with a servo motor and original control program, stable stop angle and stop time are secured. As a result, high-precision angle control is achieved.

(Stop angle accuracy:±0.2)

No consumables such as brake pads are needed since conventional hydraulic brakes are no longer necessary. |

|

|

|

|

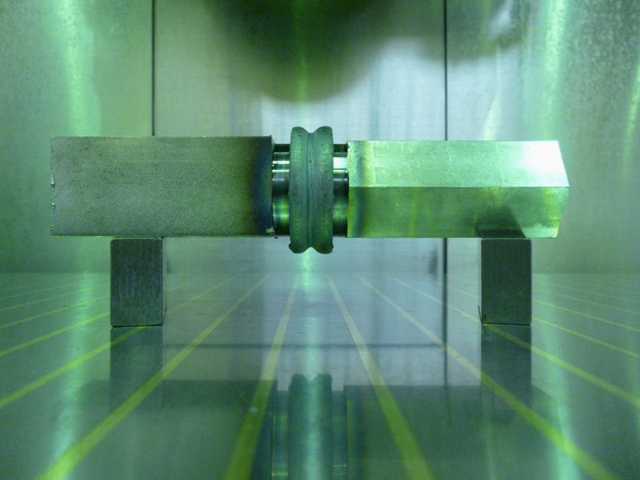

By controlling forge force with 1)servo motor, 2)ball-screw structure and 3)original control program, high-precision position control and stable drive are achieved without being subjected to oil temperature.

Forge force measured by load cell is feedback controlled by original program, and as a result smoother drive is achieved. |

|

|

|

Contact

Us

Contact

Us